With Mycelium for the future of mankind – Interview with Mihály Minkó

What are the challenges and limitations a researcher is faced with while pursuing an important matter, searching for alternatives to replace plastics? Mihály Minkó and Dóra Szilágyi are experimenting with bio-composites, using Mycelium extracted from fungi, at MOME’s laboratory, which have the potential to replace the irrationally excessive use of environmentally harmful plastics in the future. We asked Mihály Minkó to share his thoughts.

Data visualisation expert Mihály Minkó won a tender at the Innovation Centre in autumn 2021, sparking his fascination with Mycelia. He works with Dóra Szilágyi, who has already developed a progressive research programme in the subject, which means their research have some overlaps.

What exactly is a Mycelium-based bio-composite?

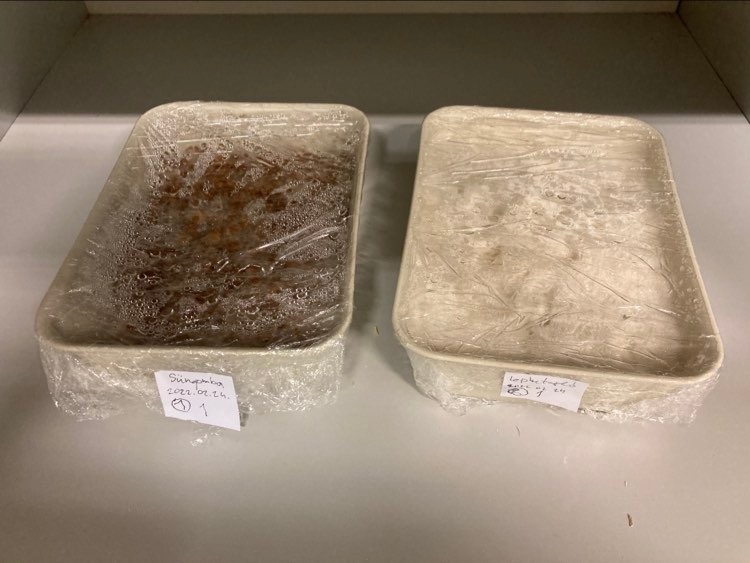

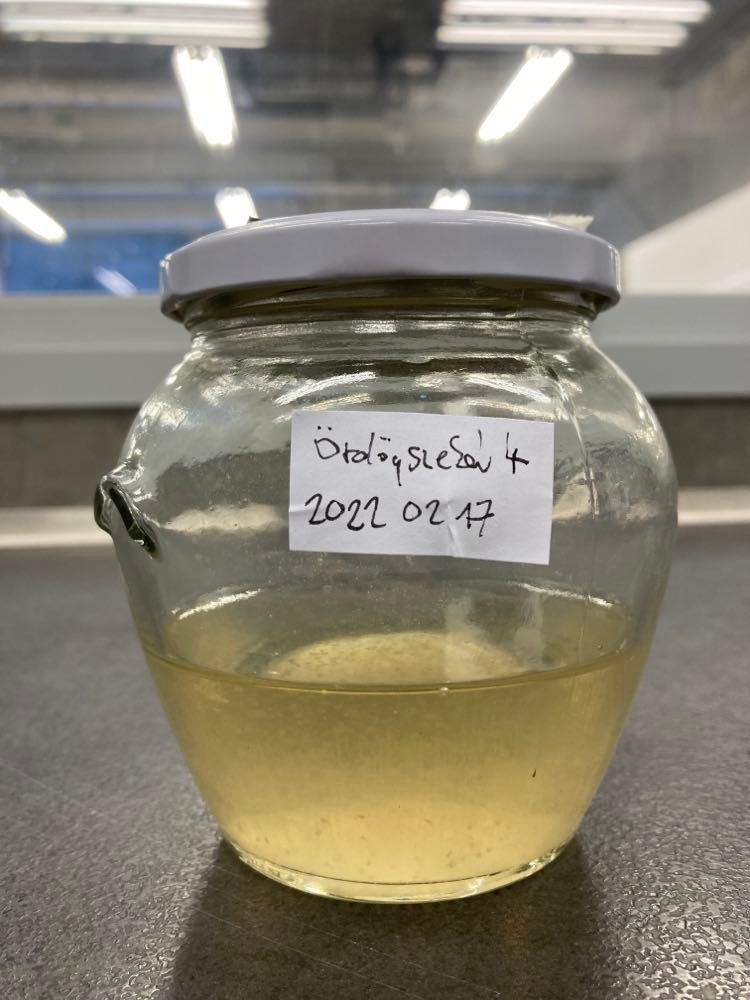

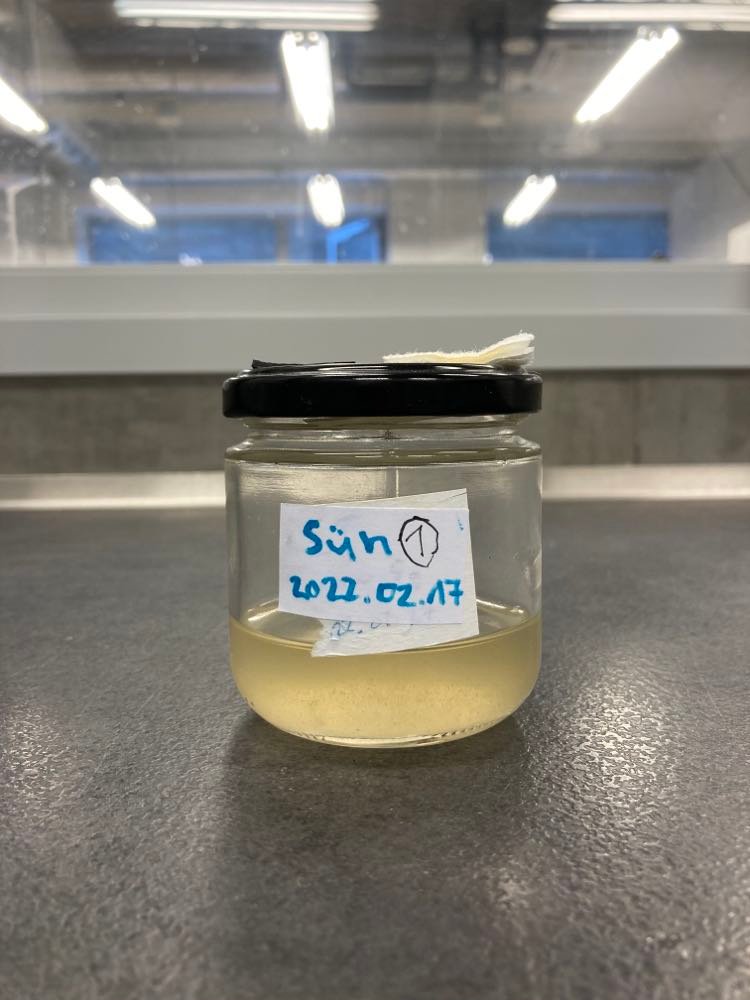

It is what you get when you take a substrate (basic material) and get it webbed through by a living organism such as a fungus, then treat it, dry it, and use a substance to practically kill the fungus. The resulting bio-composite will be fit for further use.

What properties does it have, what is it comparable to?

The consistency is somewhere between polystyrene and cork. It is highly porous, very light but also slightly fragile and crumbly, and, depending on the species of fungus used, can have different properties. It can be harder or softer, some will be more densely webbed through, and absorption can also vary. Interestingly, it is fairly fireproof, and when catching on fire, it has minimal smoke emission, which makes it ideal for insulation.

It has a wide range of applicability from packaging to construction, and could potentially replace single-use plastics. If it performs so well and there’s a demand for it, how come its research and development is not a top priority?

Because there have never been this much concern about the use of plastic before. More and more people are beginning to realise that the very water they drink has microplastics, but it’s a long process. It is completely clear to the younger generation, only it would be great if it didn’t take twenty years until they get to make the decisions.

“This is ordinary human inertia, the inertia of the masses that has prevented Mycelia from entering public awareness.”

If given a choice, people will always buy the cheaper, hassle-free alternative. This is exactly why it’s not easy to convince them to buy these types of products. Unfortunately, this is the economic reality at the moment.

These days the search for and use of alternatives to replace plastics is critical. Can biodesign – living organism-based materials – can offer a relevant solution to this challenge?

It is a highly relevant field these days, as more and more signs points to the necessity of transforming our economy to reduce waste production and the exploitation of natural resources. In order to achieve this, it would be important to use the elements found in nature to produce biodegradable products, and rid our planet from the incredible amount of plastic waste we’re still producing.

What competences are required by this field? Do you need to be a professional biologist and chemist to work on these research, or is it enough to have curiosity and an openness for experimentation?

It is useful to have a background in mycology, but since this bio-composite can also be produced at home, I’d say being a jack of all trades is best, especially if you can learn from your own mistakes. At any rate, since you need to rigorously record the conditions in which the work is done and monitor what’s happening to the living organism, shifting into a classic researcher attitude is not that difficult.

When do you think it will be suited for everyday use?

Even though many people have started intensively looking into it, it’s going to take at least five, if not ten years for it to become widely used.

“It is encouraging to see more and more multinational companies making this shift and not only producing Mycelium-based bio-composite products but also becoming actively involved in recycling plastic or waste, and its incorporation into the process of product design and development.”

Obviously I can’t tell if it’s more about marketing or a real commitment – time will tell.

What economical implications would a market launch have?

You need aseptic conditions to produce this material, everything needs to be disinfected, which is not a trivial operation and is also costly. On the other hand, many would pay a bit more for a product they know will not end up in the ocean, as opposed to some very cheap packaging materials.

What would be required for people to perceive the possibilities offered by biodesign as less foreign and difficult to access? Why do we see it as so distant?

I reckon on the one hand it’s because we have gotten accustomed to getting everything ready-made, and not having to lift a finger. On the other hand it’s because it requires a novel approach to how we use objects. Luckily, these items don’t last forever. They degrade and need to be replaced, but at the same time don’t pollute the environment. I’d rather have my chair come apart every couple of months than the entire biosphere.

So you think we’d need to place our relationship to objects on an entirely new footing?

There is only one decision we need to make: do we want mankind to survive and stay on this planet or not. This also includes the way we use objects and plastics. If the answer is yes, it is inevitable for us to make this shift.

// /

The cover pictrure is from the website of Material Incubator